PRODUCTION

Our research and development lab.

CONCEPT: EVERYTHING STARTS FROM A NEED

Every detail must have a clear purpose. Our research translates into technologically advanced products, developed with care towards sustainability, functionality and the production process.

DESIGN: INSPIRATION, FORM AND FUNCTION

We design pieces that combine aesthetics with performance. They come equipped with maximum comfort and functionality, in harmony with every movement of the body.

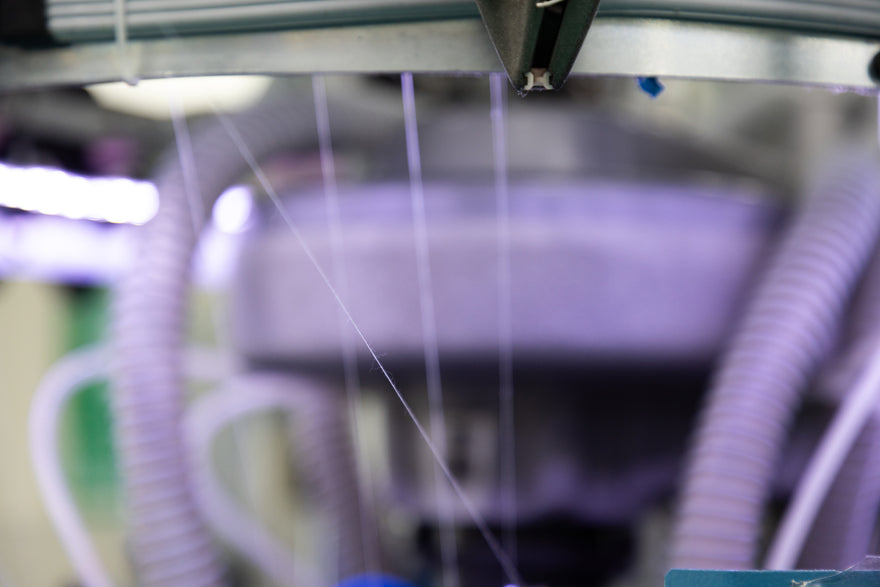

RESEARCH: INNOVATION IN EVERY FIBER

Innovation is born out of attention to detail. From the lab to the fibres, every step taken in the research process follows a rigorous method that makes sustainable progress possible and unlocks the door to new horizons.

DEVELOPMENT: WE CREATE SOLUTIONS

We look beyond what is currently possible. Every day we transform ideas into tangible solutions thanks to our expertise that ranges from textile engineering to 3D modeling and from technology to strategic vision.

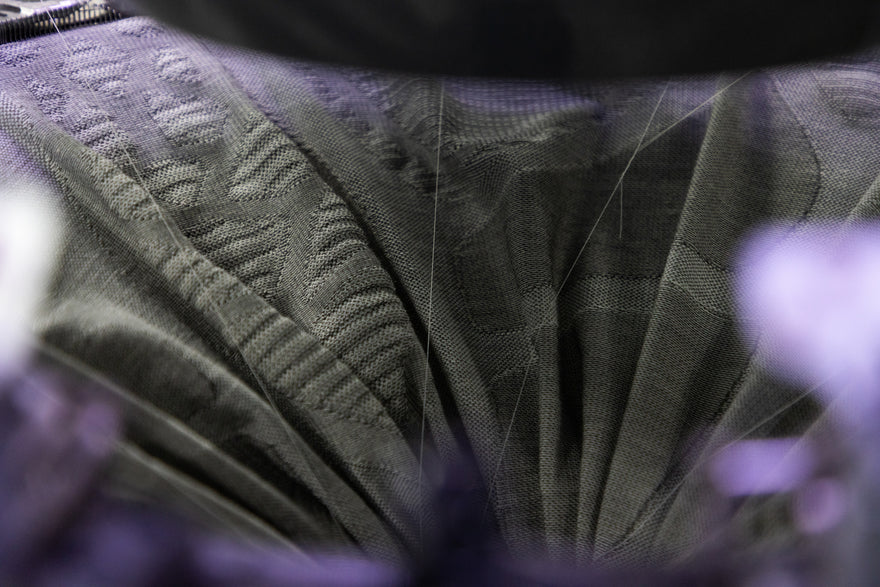

PROTOTYPING: FORM AND PRECISION

Absolute precision is the basis for every prototype. Optimised lines and shapes that adapt to the body take experience and turn it into genuine innovation.

TESTING

Each prototype undergoes authentic testing with professional athletes. Materials and products are tested under real-life conditions for measuring performance and developing new solutions.

INNOVATION: FROM THE CENTER

Every UYN product comes out of AREAS, our research and development centre. Experience guides us here across our sophisticated processes. Every phase is optimised, from the raw materials to the finished product.

PRODUCTION: IN-HOUSE SYSTEM

In Asola, a small town in Italy, we focus on research, development, creating prototypes and production. Having everything in house means quality, consistency, reduced time frames and energy saved, for the benefit of the entire process and the environment.

QUALITY CONTROL: STEP BY STEP

Right from the outset with the raw materials all the way to the packaging process, each phase is scrutinised with meticulous checks and inspections. The human eye is key; the systems measure with precision, ensuring high standards and consistency throughout the process.